About the Department

The Department of Mechanical Engineering at SEC was established in 2003, offers undergraduate (UG) and postgraduate (PG) programs in accordance with Anna University curricula, along with well-equipped laboratory. The department aims to develop next-generation engineers through an innovative teaching and learning environment, focusing on areas such as Sustainable Design, Smart Manufacturing and Automation, Robotics, Mechatronics, Industrial IoT, Thermal and Renewable Energy Systems. The department's commitment to innovation extends beyond the classroom, with faculty members actively engaged in cutting-edge research projects and industry collaboration. The department encourages participation in these initiatives and has gained hands-on experience by solving real-world engineering challenges and entrepreneurial ventures to ensure that graduates are well prepared for successful careers worldwide.

Key Features

- Innovative Learning Environment: Curriculum designed to foster creativity and practical problem-solving in mechanical systems.

- Next-Gen Technologies: Focus on emerging fields such as Mechatronics, Industrial IoT, smart manufacturing, and renewable energy systems.

- Industry-Specific Expertise: Specialized training in areas like automotive design, manufacturing, Thermal and HVAC systems.

- Real-Time Prototyping: Hands-on experience in building working prototypes using advanced 3D printing and CNC machines.

- Advanced Simulation Techniques: Exposure to state-of-the-art simulation tools for thermal, structural, and fluid flow analysis.

- Integrated Robotics Training: Extensive learning in industrial and mobile robotics for automation-driven industries.

- Collaborative learning: virtual environment to develop the real-time teamwork, knowledge sharing and efficient decision-making across design, engineering, and production teams using PLM tool

- Capstone Industry Projects: Collaboration with industries on capstone projects that solve real-world mechanical challenges.

- Smart Manufacturing: Training in digital twin technology, additive manufacturing, and Industry 4.0 applications.

- Interdisciplinary Opportunities: Collaborative projects combining mechanical engineering with AI, electronics, and data analytics.

- Sustainable Design Focus: Curriculum emphasizes eco-friendly designs and energy-efficient systems for a greener future.

- Leadership in Competitions: Consistent top performances in national-level technical events, hackathons, and innovation contests.

- Internship and Industrial Visits: Frequent industry visits and internships to bridge academic learning with industrial practices.

- Entrepreneurial Skill Development: Support for entrepreneurial ventures through incubation programs and start-up guidance.

- Global Exposure: Opportunities for student exchange programs and international research collaborations.

- Career Excellence: Tailored career guidance, resulting in successful placements in leading sectors such as design, energy, production and heavy machinery.

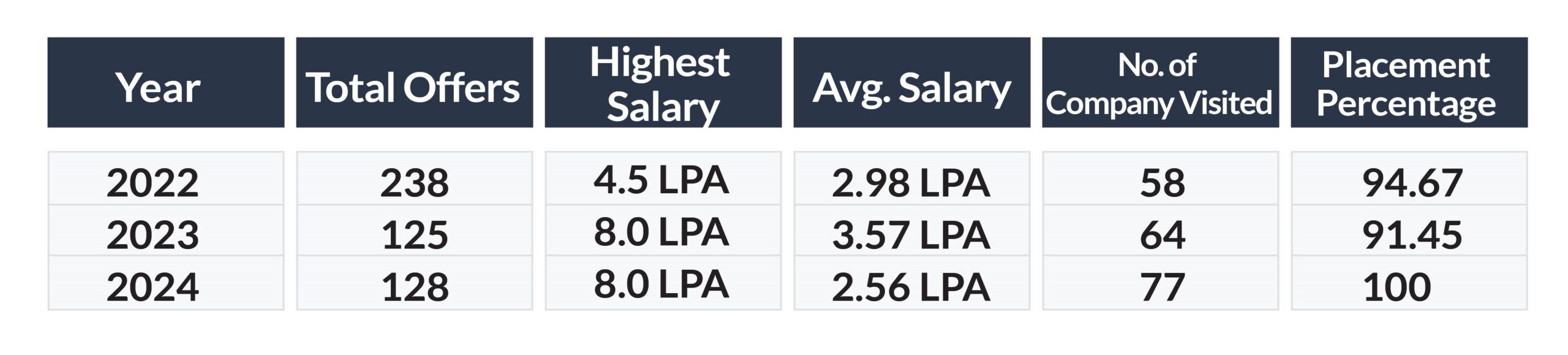

Placement Data

Centre of Excellence

Eminent Alumni

News and Events

📚 SEC: Driving Global Research Impact and Innovation

🎉 Hearty congratulations to Dr. A. Senthil Kumar, Assistant Professor, Mechanical Engineering, on his prestigious appointment as an “Early Career

🌍 Global Higher Education Milestone Achieved!

Heartiest congratulations to Lakshmanan Kodhandam (Mechanical Engineering, 2025 Batch) on securing admission to the M.S. in Industrial Engineering, supported by

💡 Innovation in Action by SEC Learners

🎉 Fourteen dynamic First-Year Mechanical Engineering learners from Saveetha Engineering College secured 1st, 2nd, and 3rd places at the Energy

VISION

The Mechanical Engineering Department strives to be recognized globally for outstanding education and research leading to well-qualified engineers, who are innovative, entrepreneurial and successful in advanced fields of engineering and research

MISSION

Imparting quality education to the students and enhancing their skills to make them globally competitive Mechanical Engineers. Maintaining vital, state of the art research facilities to provide its students and faculty with opportunities to create, interpret, apply and disseminate knowledge. To develop linkages with world class research and development organizations and educational institutions in India and abroad for excellence in teaching, research and consultancy practices.

PROGRAMME EDUCATIONAL OBJECTIVES (PEOs)

- Have high level of technical competency combined with research and problem solving skills to generate innovative solutions in mechanical engineering or related

- Be able to communicate effectively to various stake holders and practice their profession with high regard to societal needs, diversity, constraints in the professional workplace and ethical responsibilities.

- Continuously updating themselves in areas and technologies that are relevant to their career, participate in personal development and increasing their understanding of matters that are current and important to society at national and international

- Solve complex technical problems and /or design systems that are useful to society by applying the fundamental scientific principles that underpin the mechanical engineering

- Graduates are able to undertake lifelong learning and adapt to the changing environment.

PROGRAMME OUTCOMES (POs)

Engineering Graduates will be able to:

- Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem Analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using the first principles of mathematics, natural sciences, and engineering sciences.

- Design/Development Of Solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for public health and safety, and the cultural, societal, and environmental considerations.

- Conduct Investigations of Complex Problems: Use research-based knowledge and research methods including design of experiments, analysis, and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern Tool Usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The Engineer and Society: Apply to reason informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and Sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and Team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project Management and Finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-Long Learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

PROGRAMME SPECIFIC OUTCOMES (PSOs)

- To develop product/process design for mechanical systems.

- To evaluate the mass and energy flow in thermal systems

- To select suitable manufacturing process to meet industrial requirements.